Pharmaceuticals

The modern pharmaceuticals industry uses high-speed production lines requiring fast printers and coders that must keep up. Our CIJ and laser coders can be installed in any high-speed production line without compromising quality. The ability to code in any orientation makes installation simple with minimal impact on your existing workflows. Long flexible CIJ conduits allow printhead positioning into most production line setups, whilst articulated arms and compact marking heads on our lasers make integration into your pharmaceutical line quicker than most, reducing your downtime and the need for retro-engineering of your production line to accommodate new coders.

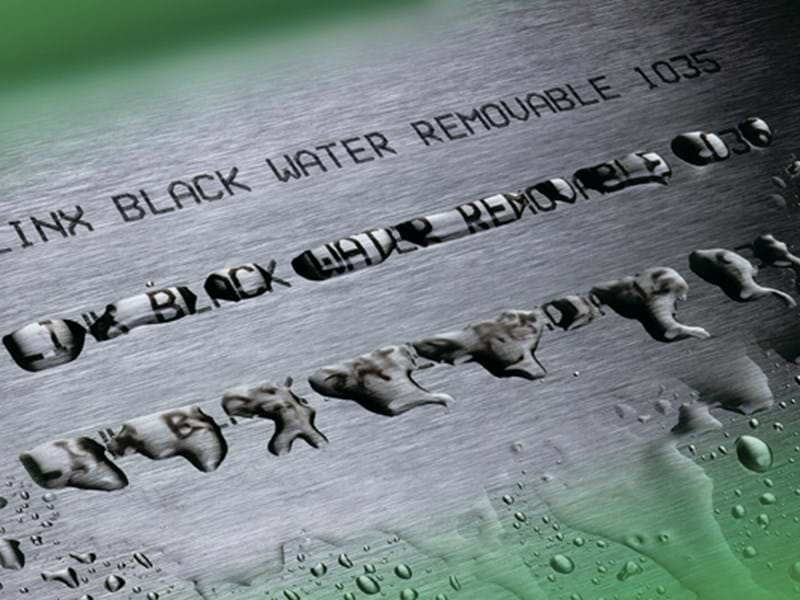

We offer a pharmaceutical coding range with printers and inks specifically designed around the needs of pharmaceutical companies. Our coders can meet your requirements for high line-speed environments, very small code printing, food grade inks for ingestible products, and cost-effective manufacturing. Our range of specialist inks allows pharmaceutical products to be safely and effectively marked. Food-grade inks can be used to mark ingestible products, like capsules, or UV-readable inks for anti-counterfeiting measures.

Ensure that your pharmaceutical coding solutions are within the requirements of the EU Falsified Medicines Directive (FMD) – consider the best technologies for your production environment, product, and complexity of code.

Continuous Ink Jet printers (CIJ) – built based on an industrial printing design that keeps ink waste at a minimum. This ensures cost-effective printing and coding for sensitive pharmaceutical manufacturing.

Linx laser coders – offering permanent, micro-printing capabilities ideal for anti-counterfeiting, or for coding directly onto capsules with codes as small as 0.8mm.

Linx Inks – UV readable inks for anti-counterfeiting and discreet codes. Food grade inks that meet FDA and EU regulations, for coding directly onto tablets. Micro printing sizes. Linx Black PE Ink 1130 – Excellent adhesion to polyethylene (PE) and most polypropylene (PP) applications.